چرا تست دوام برای دکمه ها و صفحه کلید مهم

است؟خرابی دکمه ها و صفحه کلید می تواند منجر به نارضایتی مشتری، ادعاهای گارانتی و فراخوان محصول شود. آزمایش این اجزا قابلیت اطمینان، افزایش چرخه عمر محصول و تقویت شهرت برند را تضمین می کند. تستر دوام نیروی کلیدی قابلیت های تست جامعی را ارائه می دهد که برای صنایع مختلف طراحی شده است و آن را به ابزاری ضروری برای تولیدکنندگان تبدیل می کند.

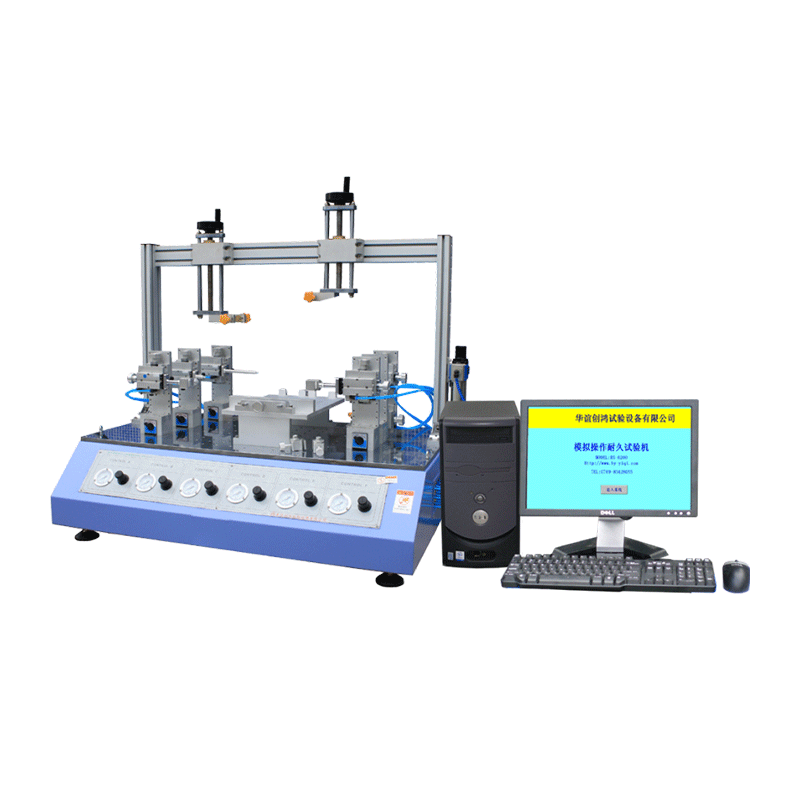

ویژگی های کلیدی تستر دوام نیروی کلیدی

1. تست پیشرفته کنترل شده توسط کامپیوتر

- رابط کاربر پسند برای تنظیم پارامترهایی مانند چرخه ها، محدوده نیرو، محدوده سفر و سرعت.

- شرایط آزمون قابل تنظیم برای فرآیندهای آزمایش مداوم ذخیره می شود.

2. حالت ها و سرعت های تست انعطاف پذیر

- حالت مداوم: 60 تا 360 سیکل در دقیقه برای آزمایش سریع.

- حالت متناوب: 5 تا 100 سیکل در دقیقه برای شبیه سازی استفاده در دنیای واقعی.

3. اندازه گیری دقیق نیرو

- مجهز به مقیاس الکترونیکی با وضوح بالا (ظرفیت 2000gf، وضوح 0.1gf).

- اعمال نیروی یکنواخت با 15 سر تنظیم بار (در صورت نیاز قابل ارتقا است).

4. چرخه های تست قابل برنامه ریزی و زمان

بندی- زمان فشار دادن و رها کردن قابل تنظیم (0.1 تا 99.99 ثانیه).

- پشتیبانی از 99,999,999 چرخه تست، ایده آل برای ارزیابی دقیق دوام.

5. تجزیه و تحلیل داده های بلادرنگ

- منحنی های جابجایی بار و نمودارهای چرخه عمر را نمایش می دهد.

- نتایج آزمایش، از جمله داده های نیرو در مقابل سفر، قابل ذخیره، چاپ و تجزیه و تحلیل است.

6. ساخت و ساز بادوام برای مصارف صنعتی

- قاب با استحکام بالا و درایو سروو موتور پیشرفته، دقت طولانی مدت را تضمین می کند.

- طراحی شده برای انجام آزمایش های صنعتی مداوم بدون کاهش عملکرد.

7. حفاظت از اضافه بار

- از آسیب تجهیزات ناشی از نیروی بیش از حد جلوگیری می کند و قابلیت استفاده طولانی مدت را تضمین می کند.

8. مجموعه لوازم جانبی جامع

- شامل سرهای تنظیم بار ، میله های ثابت و یک پلت فرم کالیبراسیون بار است.

- لوازم جانبی قابل تنظیم برای نیازهای تست خاص در دسترس است.

برنامه های کاربردی در سراسر صنایع

تستر دوام نیروی کلید به طور گسترده در صنایعی استفاده می شود که دوام دکمه و صفحه کلید بسیار مهم است. برنامه های کاربردی عبارتند از:

- ساخت صفحه کلید: دوام مواد مختلف صفحه کلید از جمله لاستیک سیلیکونی را ارزیابی کنید.

- لوازم الکترونیکی مصرفی: دکمه های تست در دستگاه هایی مانند گوشی های هوشمند، کنترل از راه دور و ماشین حساب ها.

- خودرو: از قابلیت اطمینان دکمه ها و سوئیچ های خودرو اطمینان حاصل کنید.

- بازی: طول عمر کنترلرهای بازی و صفحه کلید را آزمایش کنید.

- تضمین کیفیت: استفاده در دنیای واقعی را شبیه سازی کنید تا خرابی های احتمالی را قبل از رسیدن محصولات به مصرف کنندگان شناسایی کنید.

موارد تست پشتیبانی می شود

- تست چرخه عمر صفحه کلید

- تست دوام دکمه

- تست کلید لاستیکی سیلیکونی

- اندازه گیری نیرو و تست توزیع تست

- حداکثر بار و بار مسافرتی

- تجزیه و تحلیل سایش و پارگی

- تست مقاومت در برابر فشار دادن مکرر

- تولید منحنی نیرو-جابجایی

- تست مقاومت در برابر تماس صفحه کلید (اختیاری)

چرا تستر دوام نیروی کلید را انتخاب کنید؟

سرمایه گذاری در یک تستر دوام نیروی کلیدی به معنای اطمینان از رعایت بالاترین استانداردهای کیفیت، به حداقل رساندن نرخ خرابی و بهبود رضایت مشتری است. چه در لوازم الکترونیکی مصرفی، خودرو یا بازی باشید، این دستگاه قابلیت اطمینان و دقت بی نظیری را برای تست دکمه ها و صفحه کلید فراهم می کند.

بیاموزید که چگونه تستر دوام نیروی کلیدی می تواند فرآیند تولید شما را متحول کند. برای اطلاعات بیشتر یا درخواست نقل قول، همین امروز با ما تماس بگیرید!